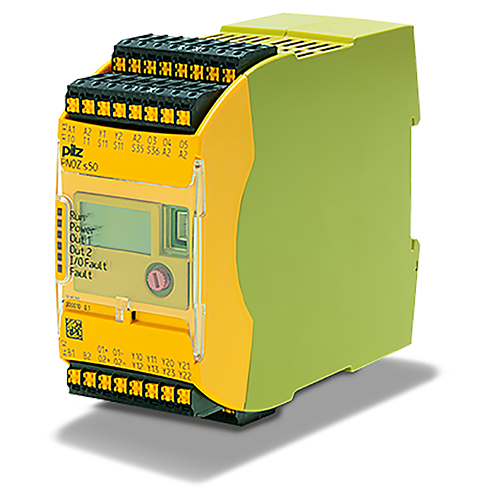

The PNOZ s50 is a dedicated safety relay designed for safe, contactless control of two brakes up to PL e. It ensures fast, reliable braking in emergencies and low-wear switching in normal operation, offering energy-efficient performance, rapid diagnostics, and broad application flexibility.

The PNOZ s50 safety relay provides high-performance and reliable brake control for both safety brakes and holding brakes, ensuring maximum protection for operators and machinery. Its ability to safely control two independent brakes up to PL e makes it an ideal solution for a wide range of applications, including gravity-loaded axes and systems requiring precise braking performance.

The relay uses temporary overexcitation followed by a user-configurable voltage reduction, achieving shorter ventilation times and lower energy consumption. This enables rapid braking during emergency situations while ensuring gentle, wear-minimizing operation during normal use, ultimately reducing maintenance and extending the service life of the brakes.

Featuring contactless switching technology with up to 4.5 A per brake, the PNOZ s50 provides fast response times and wear-free operation. Easy parameter setup and clear diagnostics through the integrated display ensure efficient commissioning and troubleshooting. Its safe digital inputs allow manufacturer-independent operation, providing great flexibility in machine integration.

The PNOZ s50 is well-suited for applications involving gravity-loaded and Z-axis movements, including stage winches, palletisers, milling machines, robot axes, scissor tables, machine tools, packaging equipment, materials handling systems, and energy/environmental machinery. It provides reliable, simultaneous control of dual brakes—especially valuable in applications like winches and lifting systems where enhanced safety is required.

| Additional Information – Safety Relay PNOZ s50 | |

|---|---|

| Brake Control Capability | Safely controls two independent safety or holding brakes up to PL e (EN ISO 13849-1). |

| Contactless Technology | Wear-free, fast response braking with up to 4.5 A per brake for efficient and durable operation. |

| Overexcitation Function | Temporary overexcitation followed by adjustable voltage reduction ensures rapid brake activation and lower energy consumption. |

| Reduced Wear | Supports fast shutdown for emergencies and slow, low-wear switching during normal operation. |

| Diagnostics | Easy-to-read display provides quick status information, parameter settings, and diagnostic messages. |

| User-Friendly Interface | Simple menu navigation via rotary knob for easy configuration and commissioning. |

| Digital Safe Outputs | Two 2-pin electronic safety outputs for 24 V DC, each supporting 4.5 A. |

| Application Areas | Suitable for gravity-loaded axes, stage technology, machine tools, palletisers, robot axes, lifting devices, packaging machines, milling machines, winches, and scissor tables. |

| Manufacturer Independence | Supports safe digital inputs for controlling brakes from different manufacturers. |

| Suitable for Gravity-Loaded Axes | Provides reliable brake control on vertical or load-bearing axes where enhanced brake safety is required. |

| Dual Brake Applications | Ideal for systems requiring two brakes, such as stage winches and lifting tables, without the need for contact-based control. |

Scan the QR to call

Website Updated On : 21 January 2026